PRODUCTS

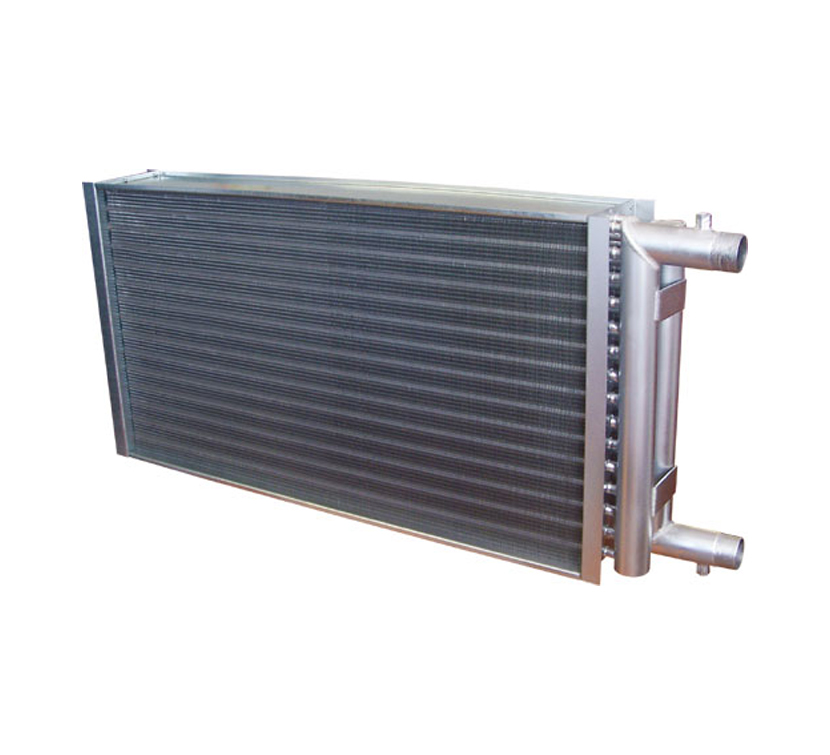

Water And Steam Coils

Water and steam batteries are produced with the required dimensions and capacities according to the needs of our customers. In order to choose the most suitable product designs, the calculations are made by using a special software program.

In our batteries, aluminium, epoxy coated aluminium or copper lamellas are used with the smooth or corrugated surfaces. The lamella thicknesses are varying from 0.12 mm to 0.20 mm depending on the needs.

Copper tubes are used with the diameters of 3/8", 1/2", 5/8". The batteries are bloated as mechanically after the fin line up process by the adjustable automatic machines, in order to provide a complete contact between and due to this process the heat transfer reaches its maximum level.

In our batteries, aluminium, epoxy coated aluminium or copper lamellas are used with the smooth or corrugated surfaces. The lamella thicknesses are varying from 0.12 mm to 0.20 mm depending on the needs.

Copper tubes are used with the diameters of 3/8", 1/2", 5/8". The batteries are bloated as mechanically after the fin line up process by the adjustable automatic machines, in order to provide a complete contact between and due to this process the heat transfer reaches its maximum level.

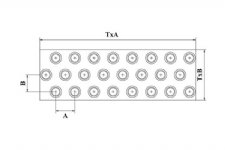

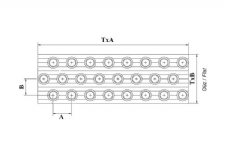

Die Geometries used in the Batteries :

» 3/8" tubes: 25x21.65mm and 31.75x27.5mm

» 1/2" tubes: 31.75x27.5mm and 40x34.64mm

» 5/8" tubes: 40x34.64mm

In the steam batteries, the tube thickness is as 0.7 mm or 1 mm to be endurable to high levels of pressures. Copper tubes are used in steam battery collectors and in steel tubes are used in hot / cold water battery collectors. Depending on the request , the collector can be made of stainless steel tube as well.

Steel fittings are used in the collectors as the standard and depending on the request, brass fittings could be used. Drains and vents are used in all our products in order to discharged the air and water.

While tube and line number are determined, capacity of customer’s need and pressure drop are considered. The most suitable cycling is chosen by comparing the pressure drop and the capacity values.

Unless otherwise stated, the batteries are tested under the pressure of 20 bars in a pool, filled with water of 40-45°C temperature. After this test, the products are washed as externally and dried.

» 3/8" tubes: 25x21.65mm and 31.75x27.5mm

» 1/2" tubes: 31.75x27.5mm and 40x34.64mm

» 5/8" tubes: 40x34.64mm

In the steam batteries, the tube thickness is as 0.7 mm or 1 mm to be endurable to high levels of pressures. Copper tubes are used in steam battery collectors and in steel tubes are used in hot / cold water battery collectors. Depending on the request , the collector can be made of stainless steel tube as well.

Steel fittings are used in the collectors as the standard and depending on the request, brass fittings could be used. Drains and vents are used in all our products in order to discharged the air and water.

While tube and line number are determined, capacity of customer’s need and pressure drop are considered. The most suitable cycling is chosen by comparing the pressure drop and the capacity values.

Unless otherwise stated, the batteries are tested under the pressure of 20 bars in a pool, filled with water of 40-45°C temperature. After this test, the products are washed as externally and dried.